和紙の持つ柔らかな透明感は、原料が育った土地の、清々しい風と美しい水と重なります。その温かみと力強さは、代々土地に根ざしてきた原料生産者の、多くの労苦ときめ細やかな愛情が実を結んだものだといえます。鹿敷製紙の紙は、長年の人と地域と自然のつながりのなかから生み出されてきました。

The softness and transparency of Japanese paper seems to represent the land where raw materials were harvested under crisp air and beautiful water. The warmth and the strength of Japanese paper comes from the effort and love of raw material farmers living in that land for generations. Through the ties of local people and nature, Kashiki Paper Co.,Ltd. has been able to produce Japanese paper.

弊社の特徴は、原料に重点を置いた紙づくりにあります。「原料に拘れ」という代々からの教えは、巷に海外原料が溢れ始めた時代から「国産に拘れ」となり、現在に至るまで鹿敷製紙の信念となっています。

What makes our company unique is the high value we put into our materials. “Use only finest materials” was the philosophy we inherited from generations ago and when the market started to depend heavily on overseas materials, our company’s philosophy changed to “Use only finest Japanese materials”. This belief is what we value at Kashiki Paper Co., Ltd. even now.

Tosa Mulberry (Kozo)

Tosa Mulberry (Kozo)

Gampi from Okayama

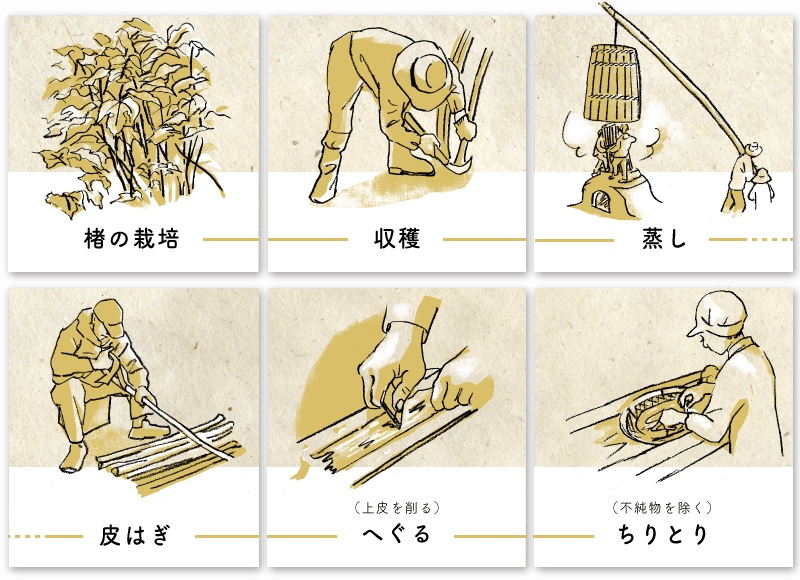

弊社では日本産の原料を使用し抄造しています。割合としては土佐楮と三椏が全体の九割を占め、その他一割を那須楮、岡山県産の雁皮を使用しています。質の良い紙を漉くため、原料には拘りが必要です。

Our paper is produced from raw materials purely made in Japan. We utilize Tosa kozo and mitsumata (90% of our paper production), and Nasu kozo and gampi grown in Okayama prefecture (around 10%). We highly value using these materials in order to produce high quality paper.

土佐和紙の里・いの町を流れる清流仁淀川。その伏流水を使った紙づくりをしています。原料を煮る、さらす、ちりを取る、漉く。紙漉きの全ての工程には水が欠かせません。豊富な水資源と自然環境が紙づくりを支えています。

The clear stream Niyodo river is located in Ino, the town of Tosa washi. When producing paper, we use underground water. It is crucial to have rich and clear water in all steps of process paper; boiling, water bleaching, removing impurities, and making paper. Abundant water resources and our natural environment support paper making.

機械·手漉きともに、手間暇を惜しまず、同様の原料処理方法を守り続けています。

We have been using the same paper making process for generations. The same method is used to process raw materials, both for machine-made and hand-made paper.

Kashiki Washi Manufacturing Process

Kashiki Washi Manufacturing Process

- 1. 煮熟 Boil

- 消石灰、ソーダ灰、苛性ソーダなどのアルカリ溶液にて、ステンレスの釜で煮る。 Boil materials in the stainless-steel pot with alkaline solution, such as calcium hydroxide, sodium carbonate, and caustic soda.

- 2. 水晒し Water bleaching

- 粗洗いした後、朝晩の手入れをしながら、仁淀川の伏流水で水晒しをする。(苛性ソーダ煮の場合は、水晒後、次亜塩素酸ソーダにて漂白し、さらに入念な水晒しを行う) Soaking the material with water which is retrieve of beneath the earth from Niyodo River. (When using caustic soda for boiling, wash the material and bleach them with sodium hypochlorite. Carefully water bleach the material again.)

- 3. ちりとり Removing impurities

- 水中で、小さな不純物を根気よく取り除いていく。 Carefully remove all impurities.

- 4. 脱水 Dehydration

- 原料の水分を取るために、脱水する。 Dehydrate the materials to remove moisture.

- 5. 打解 Beating

- 原料を適度な水分量にし、万遍なく打解機で叩く。 Moderately re-moisturize the materials and beating them evenly.

- 6. 解繊 Defibration (isolating and preparing fibers)

- 楮は、ナギナタビーターで解繊し、三椏、雁皮は、ホレンダービーターにて解繊したものを、さらにスクリーンに通す。 Use the “Naginata” beater to separate the Kozo fibers. Use the Hollander beater to separate Mitsumata and Gampi fibers. Place them over a mesh screen.

- 7. 抄紙 Paper making

- 製造ラインのビーターに原料を入れ、繊維を分散させるためにノリ(化学糊)を加える。その後、ブロンズの上に漉きあげた繊維は、ウェットの毛布に移り、水分をとりながら、ドライの毛布へと移動し、ステンレスのドライで乾燥する。 Place the materials into the beater in the production line, then add "Nori" (a mucilaginous agent) to disperse fibers. The fibers are transferred onto a bronze wire rack. Now formed by the rack into a large sheet, it is moved again onto a wet blanket. The fibrous sheet is run between two rollers, one wet and one dry. The pressure from the two rollers extracts the moisture from the fibrous sheet. Then, it is transferred onto the dry blanket and pushed forward into a stainless steel dryer to be dried completely.

地域の原料農家、加工技術者、紙漉き、卸問屋、そして使い手へ。鹿敷製紙では、伝統的な技術を受け継ぎつつ、時代の変遷に合わせて新たな活路を開拓すると同時に技術を開発し、様々な用途に応じて紙を開発してきました。紙漉人確保の観点から、昭和四十九年に短網抄機を設置しました。手漉き紙を機械で抄くという考えから、原料処理は手漉き紙と全く同一の処理方法で行っています。かつ手漉き紙に似合った地合いを作るため、機械の回転を非常に遅くするなど技術面においても留意した結果、手漉き和紙に勝るとも劣らない高品質な紙を抄紙する事が可能となりました。

Paper is passed on, starting from local raw material farmers, to processors, to paper producers, to dealers and then to users. Kashiki Paper Co., Ltd. have not only passed down the traditional paper making skills but has also been a pioneer in inventing new skills over time. We have invented new types of paper to match various usages. Although we started using the machine from 1974, we wanted the paper making process to be as similar to the hand-made paper process as possible. Therefore the same materials have been used for production. Moreover, in order to produce the same texture as hand-made paper, we studied the machine and decided to slow down the rolling process. As a result, our machine-made paper is as good as high quality hand-made paper.

実は和紙という言葉が指す「紙」についての明確な定義はありません。しかし、「本来の和紙」とは「和紙は1000年、洋紙は100年」という言葉が表す通り、保存性が極めて高いものであったと考えます。

弊社はこの保存性を重視し「本来の和紙」を目指し国内産原料にこだわり原料処理を手漉きをしていた時と同じ工程を経て作り続けています。弊社では鉄分が紙に害を及ぼすと考え、ドライ、釜、アームなどにはステンレス、または真鍮を使用しています。

In fact, there is no clear definition what kind of “paper” washi is. There is a saying in Japan, “Washi lasts 1000 years and yo-shi lasts 100 years.” From this saying, we believe “genuine washi” had excellent storage stability. We value preservability and with the aim to produce “genuine washi,“ we use raw materials grown in Japan and apply the same production method from the old times to process raw materials. We have avoided using iron for parts like the dryer, pot and arms of the machine and so on. We introduced stainless-steel and brass to maintain the paper longevity, and to stay “genuine”.

昭和57年、鹿敷製紙2代目の濵田繁信はフランスにて修復の現場を見学し、その後すぐ機械抄きによる修復用紙を開発しました。以降、修復用和紙は国内の古文書や国宝の修復はもとより、世界中の美術館や博物館で認められ、現在も継続して使用されています。代々の教えを守り愚直に日本本来の和紙づくりに努めてまいります。

In 1982, HAMADA Shigenobu, the second Representative Director of Kashiki Paper Co., Ltd, visited restoration sites in France. As soon as he returned to Kochi, he developed the ultra-thin kozo paper to be used for restoration. The paper soon received acknowledgment and since then it has continued to be used to restore ancient documents or national treasures in Japan, as well as art galleries and museums around the world. We intend to make conscientious efforts to make genuine washi to keep the techniques of generations.

和紙は表面張力が強く、空気の層を作って吸湿や吸音効果があります。襖や障子、天井や壁紙に。天気の良い時には空気を外へ逃がし、悪い時には湿度を取り込み、五感と暮らしに寄り添います。

Washi has high surface tension and is flexible. It also creates layers of air which shuts out sound and humidity. That is why it is widely used for fusuma and shoji (papered sliding doors), ceilings, and wall paper. During good weather the air seeps outside through the paper and during bad weather the humidity stays inside. This paper complements the people’s five senses and their lifestyle.

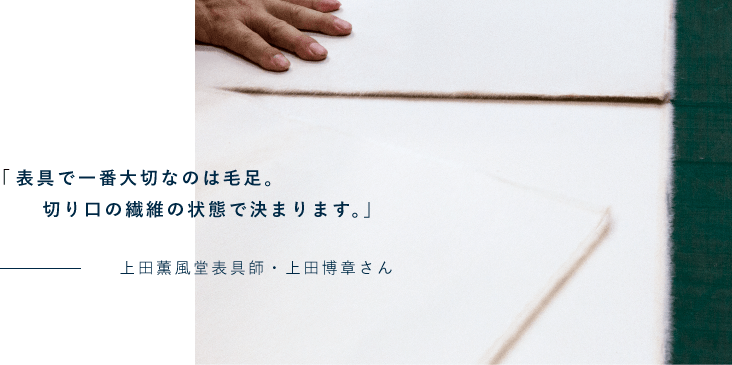

— Hiroaki AGETA from AGETA kunpudou

耐久性のある「鹿敷和紙(信風)」は幅広い分野のユーザーの方々から高い評価をいただいており、美術品修復家、装丁家、書家、版画家、デザイナー、建築関係など、業種の枠を超えて活用されています。

The durable Kashiki Washi (Shinpu) is highly valued among users from distinct fields, including art restorers, book designers, caligraphers, woodcut print makers, designers, the architecture industry, and others. Through them, the paper is utilized in various fields.

「良い紙を漉けば用途は後から開けてくる」という先代の思いは、現在も鹿敷製紙における紙づくりの精神となっています。様々な用途に素材としてお使い頂けるように、薄い紙から厚い紙まで(3g/㎡~100g/㎡)、高品質を目指した製品づくりをしています。

Our predecessor believed that “when fine paper is made, it will be utilized unlimitedly” and that has been Kashiki Paper Co.,Ltd.'s core value. In order for the users to use our paper for various situations, we provide thin to thick papers (3g/m2~100g/m2) with consistent quality.